More Than Leather. It's a Promise.

In a world of fast-fashion and products that fall apart, we’ve chosen a different path. We believe the items you carry every day should be dependable, beautiful, and get better with time.

That’s why we don’t just use leather; we’ve built our brand around 100% full-grain, vegetable-tanned leather. It’s the simple reason our products will last you a lifetime, not just a season.

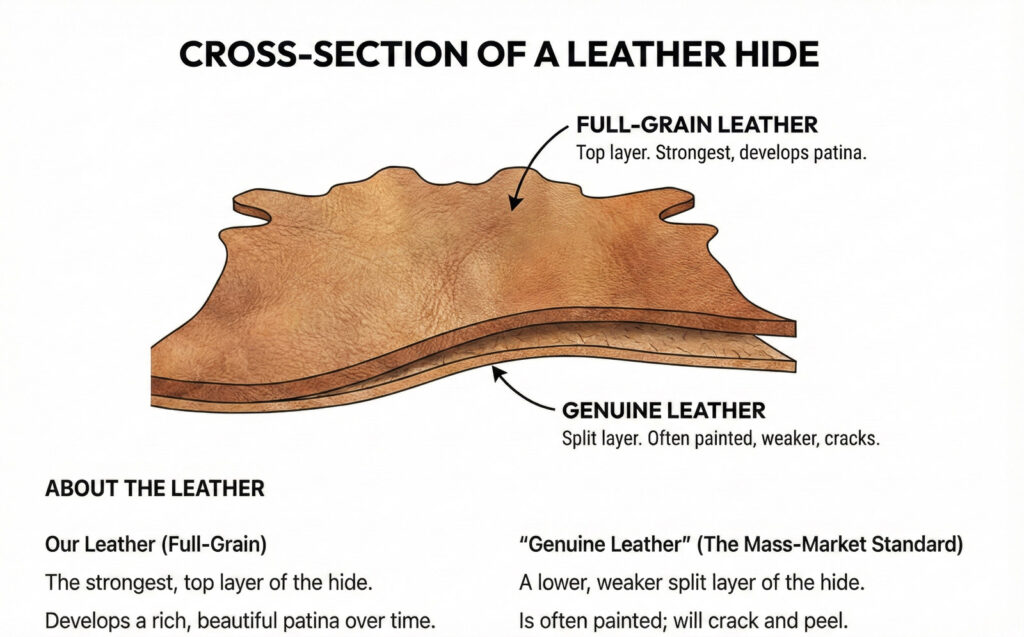

Not All Leather Is Created Equal

The term “leather” is confusing. Most bags or wallets are made from “Genuine Leather,” which is a marketing term for a cheap, weak material. We believe you deserve to know the difference.

A Lifetime of Character: The Benefits

Durability and Longevity: Our leather is known for being incredibly strong and resistant to wear. It’s designed to last a lifetime, aging gracefully rather than deteriorating.

Aesthetic Appeal and Patina: Unlike chrome-tanned leather, our veg-tanned leather develops a rich, unique “patina” over time – darkening and gaining character from sunlight and natural oils.

Eco-Friendliness: We use natural tannins from plants, making the process more environmentally friendly than chemical-heavy alternatives.

Unique Scent: Many appreciate the distinct, earthy, and natural scent of vegetable-tanned leather, a hallmark of traditional processing.

Our Craft: The Art of Vegetable Tanning

This isn’t the fast-fashion approach. Our leather is created using a slow, traditional method called vegetable tanning. It’s an artisan process that takes weeks, not days, and relies on natural tannins from tree bark and plants.

Preparation (Pre-tanning): The hides are first cleaned, salted for preservation, and soaked in a lime solution (liming) to remove hair, fat, and unwanted residues.

Tanning: The prepared hides are then immersed in large vats or rotating drums containing a concentrated solution of tannins. These tannins are naturally occurring polyphenols extracted from the bark, wood, leaves, or fruits of various plant species, such as oak, chestnut, or mimosa .

Conversion: Over many weeks, the hides are gradually moved through solutions of increasing tannin concentration. The tannins bond with the collagen proteins in the hide, effectively displacing the water, which stops the hide from rotting and permanently changes its structure into leather.

Finishing: Finally, the tanned leather is dried, oiled, stretched, and often dyed to achieve the desired texture and finish.

This slow, meticulous method is what gives the leather its thick, firm, and durable character. It’s a craft we’re proud to support.